Apache-MultiSENS™

Technology That Makes a Difference

Military & Industrial Applications

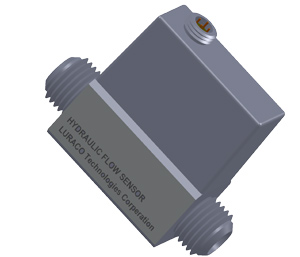

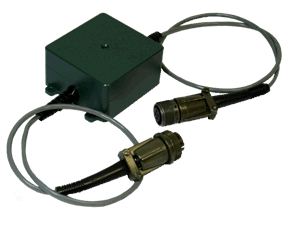

Funded by U.S. Army, LURACO Technologies has successfully developed an intelligent Multi-tasked Sensor (MultiSENS™) that is used for engine hydraulic system monitoring in U.S. military aircraft. Patent No. US 7,891,234 B1.

MultiSENS can replace the mechanical based Delta P indicator that is currently being used on legacy military aircraft without interfering with wiring harnesses or requiring system modification. The basic function of MultiSENS automatically analyzes and reports multiple aircraft hydraulic system parameters. MultiSENS is a complete sensing device that uses an advanced sensor package to measure the differential pressure, contamination, and temperature of hydraulic fluid. Data captured by MultiSENS is available for download wirelessly.

This technology provides a stand-alone multi-task intelligent system that will be used in Apache Helicopter “AH-64”. MultiSENS-AH-64 was designed to improve the performance and service life of aircraft as well as reducing direct costs such as fuel, damaged components, and labor.

MultiSENS provides the military, and other users of hydraulic equipment, with an automated and intelligent solution to enable specific maintenance to be completed based on fluid and filter status. MultiSENS provides the user with intuitive visual indications of unsafe fluid contamination levels, temperature, and filter differential pressure. Sensor data is stored within the MultiSENS device and is downloadable to an analysis tool so that the user can identify fluid and fluid filter deterioration trends.

The developed technology for MultiSENS has a significant impact on the current condition-based engine health monitoring within the military, including the Army, Navy, and Air Force. This novel technology can be used on any legacy or future aircraft, and ground support equipment that uses hydraulic or lube filtration. It opens up opportunities to explore additional applications of this technology on other weapon systems.

MultiSENS-AH-64 Features:

- Measure multiple hydraulic filters and fluid parameters (pressure, contamination level, temperature), and perform on-board intelligent data processing

- Seamlessly replace AH-64 mechanical Delta-P indicators

- Estimate the remaining life of hydraulic filter

- Advanced sensor technology, which eliminates mechanical-based modes of failure and improves accuracy

- Proper maintenance action must be performed before status LEDs can be reset

- LED warning and alert indicators

- Wireless data downloading

- GUI Software application (MultiSENS-VIEW™)